Get more infos.

Save Time And Money

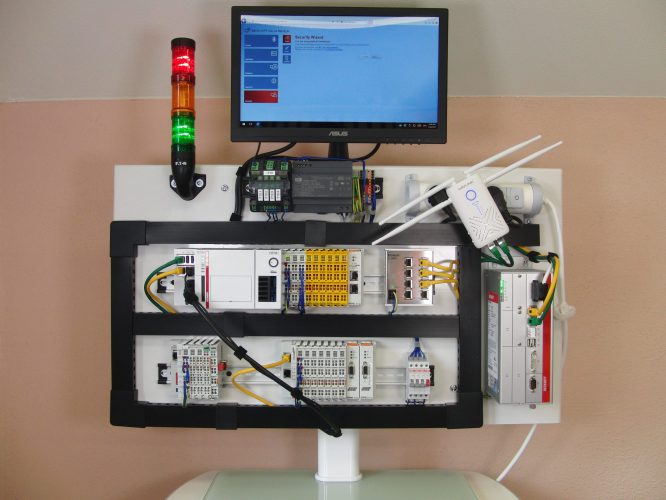

Commissioning with virtual models

Our Offer

We provide virtual commissioning as an add-on service – you decide for yourself whether you’d like to benefit from it.

Benefits

- Time and travel costs are minimized. The majority of the commissioning process can take place in our office.

- Project duration is significantly shortened, because the software can be tested in our virtual hardware environment parallel to design and installation.

- After delivery to the customer, unexpected behavior can be reproduced off-site and potentially without also having to take the plant partially out of production.

- Retrofit special case: Length of production downtime can be shortened considerably. Plant production can recommence weeks earlier, a not insignificant cost factor.

Downsides

- In total, more time is required for the project due to the modeling of the digital twin.

- After the hardware has been commissioned, the digital twin may still need to be refined.